Concrete as a CO2 reservoir: what's the point and what is homeopathy?

Concrete is an irreplaceable building material, especially for basements. This raises the question of how emissions can also be reduced in concrete and how concrete can become a CO2 storage location, as Openly sees buildings as CO2 storage facilities.

Reduction of concrete volume

First and foremost, architects and engineers are called upon to use as little concrete as possible. The dimensions must be reduced. For approx. 4 cubic meters of concrete, 1 ton of CO2 can be saved, which in turn corresponds to approx. 5000 car kilometers.

In the Valley Widnau pilot project the volume of concrete was reduced from 1500 to 903m³ by a change of engineer, which meant a saving of 130 tons of CO2 or almost 1kg/m² EBF.

However, it's like tobacco advertising - which manufacturer wants people to smoke less?

Carbon capturing = biochar

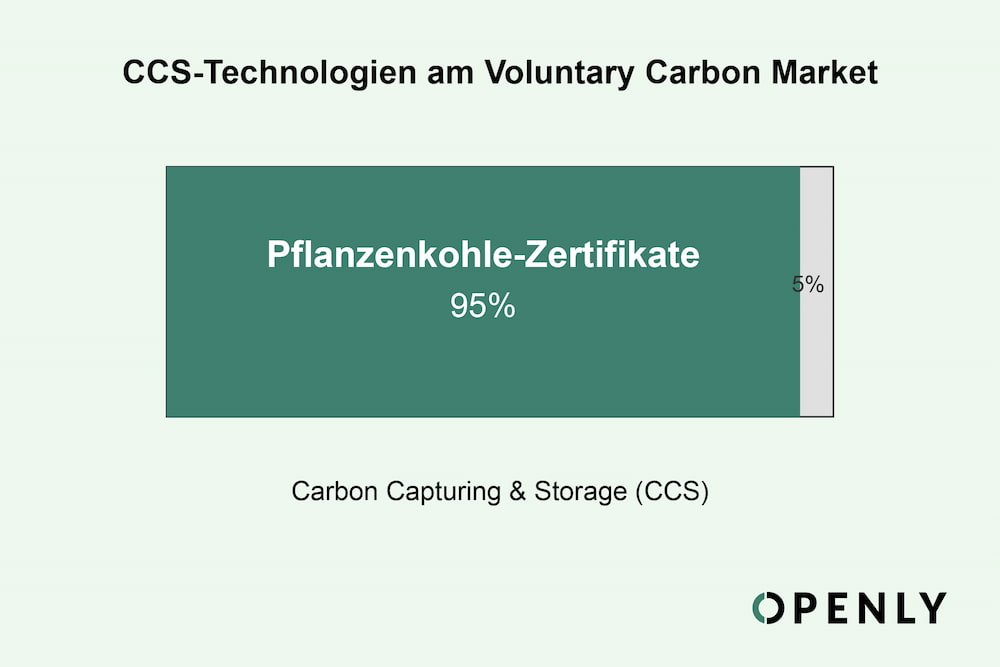

Over 95% of today's CCS (Carbon Capturing & Storage) technologies traded on the Voluntary Carbon Market are biochar certificates. (Link: European biochar certificate) This coal is obtained by pyrolysis, in which biogenic waste (usually wood chips) is carbonized in the absence of oxygen. The CO2 bound in plants is thus bound for 1000+ years, regardless of whether it is used as animal feed for cows, in civil engineering, for example in sponge city projects, or in concrete. One of the leading manufacturers of such plants is Syncraft.

Concrete as CO2 storage using biochar

It is an obvious step to also use biochar in concrete, as it can also be stored there in the long term, even during dismantling and recycling. The effect is considerable with over 100 kg of CO2 reduction per m³.

How it works:

With around 1.5% added to the conventional concrete mix, CO2 storage of approx. 100 kg per m³ can be achieved at an additional cost of approx. 100 euros/m³ ready-mixed concrete. Sand is substituted and the concrete is given the color anthracite.

It is important to note that the emissions from concrete remain (same gross balance) and are partially compensated for with biochar (approx. 40% better net balance).

The Valley Widnau pilot project set a record by using 300m³ in a single day. We did this to prove the industrial applicability.

From now on, biochar concrete can be realized worldwide with a lead time of 2-3 months with our partner CarStorCon. The Openly consulting team for your construction project.

The best thing about it: as the client, you get the same concrete quality and the CO2 reduction certificate free of charge - for the neutralization of your core business.

Overall balance is crucial

Not every building material has to be "climate neutral" for a new build or renovation. The approach to construction projects is always the same: the primary aim is to prevent CO2 emissions and use building materials with as little CO2 as possible. In the field of concrete, cement manufacturers are currently making massive progress with a number of new products. Ask your concrete supplier directly!

Openly warnt ausdrücklich vor “Klima”-Anbietern auf dem Markt. Bitte fragen Sie explizit nach einer Brutto-CO2-Bilanz. Denn einerseits gibt es Produkte, die nur homöopathische CO2-Senken erzielen (<6 kg/m³) oder – noch problematischer – deren Brutto-Bilanz schlechter als normaler Beton ist oder Senken bereits an Dritte verkauft wurden (das heisst, der Beton enthält gar keine Senke mehr).

Outlook

CCS at cement factories: The main problem with the carbon footprint of concrete is the cement (burnt lime - the CO2 it contains escapes during this process). The first pilot plants are already in operation today, which capture the CO2 released from cement plants and store it geologically. If it were possible to produce cement in a CO2-neutral way, concrete would be back on the winning track, albeit with a significantly higher concrete price.

Biochar granulate: EMPA and other manufacturers are currently researching the development of a type of granulate or stone made from biochar. This could replace gravel in concrete and massively increase the CO2 sink in concrete. Concrete would become a "climate saver" or "final storage site".

CO2 capturing in fresh concrete: The Canadian-based company Carbon Cure has developed a process for capturing CO2 during concrete production. In principle, the concrete (or lime/cement) already does this on its own. In our opinion, the process is very promising, which has also prompted Microsoft and Samsung to make a 100 million investment.